1

In addition to scientific endeavours and the discovery of new material resources, one of the necessary ways for a better future can be to consider a radical transition from a linear economic model, in which most consumed materials turn to waste, to a circular economy,1 where we return products and materials to production and therefore at least extend their service life.

Europe alone produces 2.5 billion tonnes of waste a year, of which around 50% ends up in landfills or incinerators.2

The global economy is currently only 8.65% circular (according to the World Gap Report 2020). Worldwide, 100 billion tons of material were applied in 2020, of which only 8.65% were secondary raw materials. In 2018, it was 9%, so in recent years the global application of the circular model of the economy has decreased.3

So, the problem arises not only in how much raw material humanity consumes but also in how it handles it.

At present, waste management largely still corresponds to the linear model mentioned above.4 However, waste is generated not only at the end of the product's life cycle but also during its production, in large quantities. We call such waste pre-consumer waste. Waste that is generated only after the manufactured item expires is called post-consumer waste.

The global economy is currently only 8.65% circular (according to the World Gap Report 2020). Worldwide, 100 billion tons of material were applied in 2020, of which only 8.65% were secondary raw materials. In 2018, it was 9%, so in recent years the global application of the circular model of the economy has decreased.3

So, the problem arises not only in how much raw material humanity consumes but also in how it handles it.

At present, waste management largely still corresponds to the linear model mentioned above.4 However, waste is generated not only at the end of the product's life cycle but also during its production, in large quantities. We call such waste pre-consumer waste. Waste that is generated only after the manufactured item expires is called post-consumer waste.

4

The concept of circular economics is to prevent the generation of pre-consumer waste and to limit and reuse post-consumer waste.

Simply put, it is the principle of finding solutions for optimal material utilisation (application and utilisation of materials and waste that are produced on earth), the use of more environmentally friendly energy sources and the effort to extend the life of products. Usually, the concept of circular economics is described in the Butterfly Diagram (pic. 1) by the Ellen MacArthur Foundation, which illustrates two types of cycles. A biological cycle that includes biodegradable materials that help enrich soil or agriculture and can decompose. The second, the technical cycle, which includes all other types of materials (metals, plastics, etc.), for which people should ideally try to find a new use and a new way of processing, as it is not possible to return them to nature.

As a designer, how is it best to proceed according to the concept of circular economics?5

Simply put, it is the principle of finding solutions for optimal material utilisation (application and utilisation of materials and waste that are produced on earth), the use of more environmentally friendly energy sources and the effort to extend the life of products. Usually, the concept of circular economics is described in the Butterfly Diagram (pic. 1) by the Ellen MacArthur Foundation, which illustrates two types of cycles. A biological cycle that includes biodegradable materials that help enrich soil or agriculture and can decompose. The second, the technical cycle, which includes all other types of materials (metals, plastics, etc.), for which people should ideally try to find a new use and a new way of processing, as it is not possible to return them to nature.

As a designer, how is it best to proceed according to the concept of circular economics?5

5

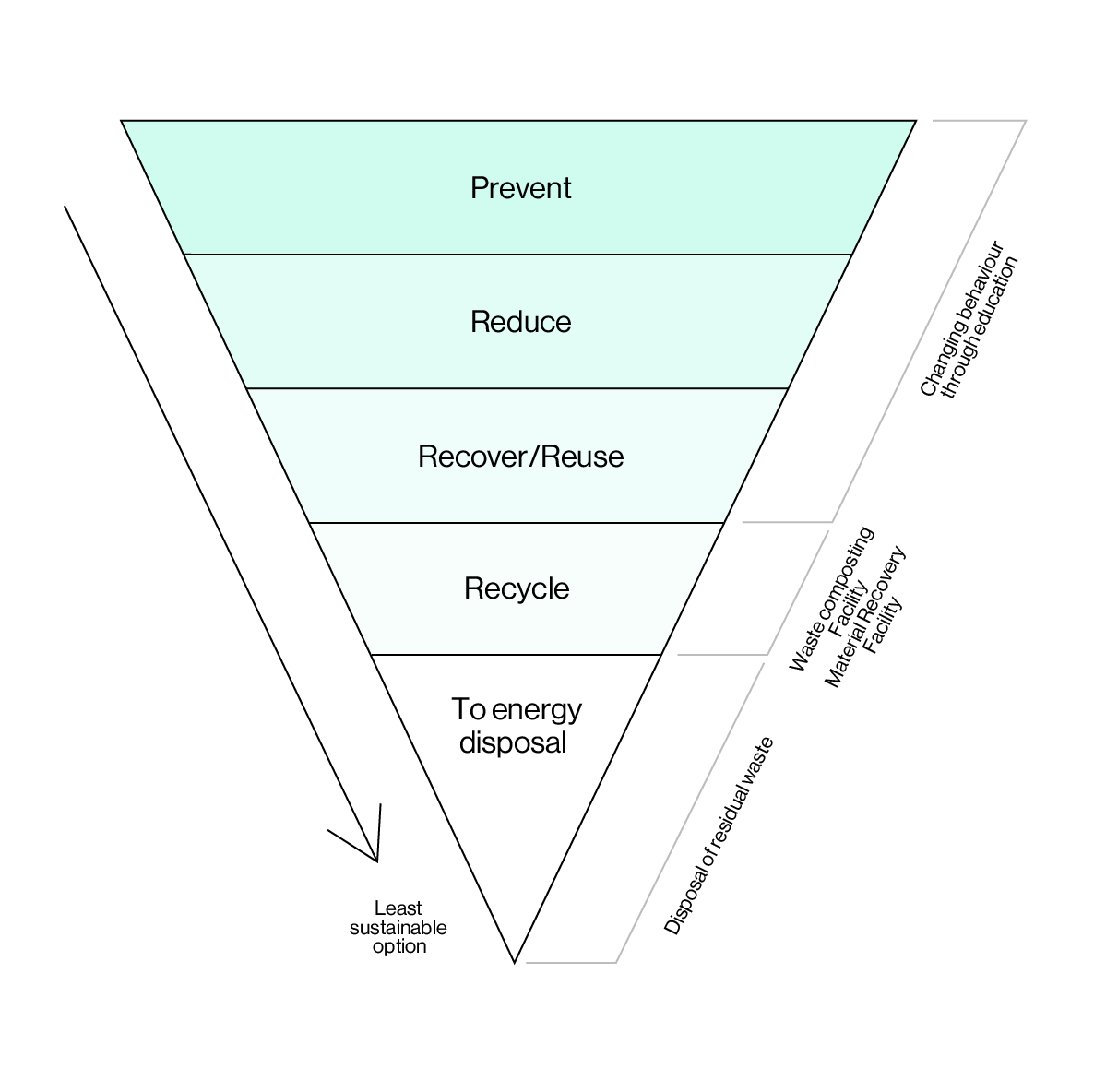

︎︎︎Primarily, it is very important to prevent the generation of waste. The effort to minimise the already mentioned pre-consumption waste should especially resonate with the manufacturers and the technologies they use.

︎︎︎Another desired goal should be to reduce the amount of materials used. An example is the Soapack design soap dishes and other cosmetics. Designer Mi Zhou created these containers from the soap itself and thus devised an alternative to plastic or glass packaging materials. If the container is not subsequently reused, the negative environmental impact of the plastic and glass material is comparable.6

︎︎︎If the material/waste has already been generated, the next ideal option may be to reuse it. The concept of reuse is based on the use of materials and products several times without being significantly technologically processed (this saves energy unlike the recycling process). The Rotor studio in Brussels, for example, works with the idea of material reuse. In its work, it generally develops a critical attitude towards material management through research and design. In addition to projects in the field of architecture and interior design, the studio also designs exhibitions, books, economic models and political systems. With other partners in 2019, it started a subsidiary called Rotor Deconstruction. It is a pioneering cooperative company in Brussels, which operates in the field of dismantling, modification and sale of regenerated components.

The NAHAKU product and interior studio deals with the use of materials from end-of-life products in the Czech environment. The last product it introduced (Designblok 2020) was a glass door made of washing machine doors. It also manufactures, as an example, lighting from disposable prosecco containers (Designblok 2019).

Product repair is also related to reuse. Product repair has been an automatic practice throughout history. With the advent of modern capitalism and the development of industry, people became accustomed to the possibility of buying an almost infinite number of products at low prices. Unfortunately, the possibility of repairs has receded into the background. In recent years, however, we have seen a number of initiatives and individuals seeking to arouse public interest in origin, quality and consideration, and to initiate the necessary need to re-evaluate products and materials. It is the designers and artists who play a role in this discourse and social awareness.

︎︎︎Recycling is in fourth place in the hierarchy of preferred waste management - it is a very demanding process, both in terms of logistics and energy. Therefore, it is advantageous only if the recycled material can actually be applied subsequently (more about recycling in text C).

However, from the point of view of a circular economy, less preferred options for waste management are incinerators and energy recovery (ZEVO).

Ultimately, the most unsuitable option is the waste ending up in landfill. Unfortunately, this is currently the most common way in which waste is treated. However, in 2019, the European Commission approved the transition to a more sustainable EU economy (The European Green deal).7

︎︎︎Another desired goal should be to reduce the amount of materials used. An example is the Soapack design soap dishes and other cosmetics. Designer Mi Zhou created these containers from the soap itself and thus devised an alternative to plastic or glass packaging materials. If the container is not subsequently reused, the negative environmental impact of the plastic and glass material is comparable.6

︎︎︎If the material/waste has already been generated, the next ideal option may be to reuse it. The concept of reuse is based on the use of materials and products several times without being significantly technologically processed (this saves energy unlike the recycling process). The Rotor studio in Brussels, for example, works with the idea of material reuse. In its work, it generally develops a critical attitude towards material management through research and design. In addition to projects in the field of architecture and interior design, the studio also designs exhibitions, books, economic models and political systems. With other partners in 2019, it started a subsidiary called Rotor Deconstruction. It is a pioneering cooperative company in Brussels, which operates in the field of dismantling, modification and sale of regenerated components.

The NAHAKU product and interior studio deals with the use of materials from end-of-life products in the Czech environment. The last product it introduced (Designblok 2020) was a glass door made of washing machine doors. It also manufactures, as an example, lighting from disposable prosecco containers (Designblok 2019).

Product repair is also related to reuse. Product repair has been an automatic practice throughout history. With the advent of modern capitalism and the development of industry, people became accustomed to the possibility of buying an almost infinite number of products at low prices. Unfortunately, the possibility of repairs has receded into the background. In recent years, however, we have seen a number of initiatives and individuals seeking to arouse public interest in origin, quality and consideration, and to initiate the necessary need to re-evaluate products and materials. It is the designers and artists who play a role in this discourse and social awareness.

︎︎︎Recycling is in fourth place in the hierarchy of preferred waste management - it is a very demanding process, both in terms of logistics and energy. Therefore, it is advantageous only if the recycled material can actually be applied subsequently (more about recycling in text C).

However, from the point of view of a circular economy, less preferred options for waste management are incinerators and energy recovery (ZEVO).

Ultimately, the most unsuitable option is the waste ending up in landfill. Unfortunately, this is currently the most common way in which waste is treated. However, in 2019, the European Commission approved the transition to a more sustainable EU economy (The European Green deal).7

1 Butterfly Diagram - Circular Economy Concept - Ellen MacArthur Foundation, illustration: Bára Růžičková

2 Circular Economics - Institute of Circular Economics. Institute of Circular Economics - We close the loop [online]. Available from: https://incien.org/cirkularni-ekonomika/

3 The world is now only 8.6% circular - CGR 2020 - Circularity Gap Reporting Initiative. Circularity Gap Reporting Initiative - Home [online]. Copyright © 2008 [cit. 11.02.2021]. Dostupné z: https://www.circularity-gap.world/2020

4 Linear economic model, illustration: Bára Růžičková

5 Procedures according to the model of Circular Economics, illustration: Bára Růžičková

6 Interview with Vladimír Kočí: We cannot see beyond the horizon with common sense. Material times. Prague: Happy Materials, 2019. ISSN 2464-742X.ii

7 So far, this is only a general plan, for which a strategy is gradually being developed - to support sustainable industry, the circular economy and related waste management. However, a bill banning certain types of disposable plastics (cutlery, plates, straws, cups) was not approved by the Czech government until January 2020. Ideally, it should apply from July 2021.

2 Circular Economics - Institute of Circular Economics. Institute of Circular Economics - We close the loop [online]. Available from: https://incien.org/cirkularni-ekonomika/

3 The world is now only 8.6% circular - CGR 2020 - Circularity Gap Reporting Initiative. Circularity Gap Reporting Initiative - Home [online]. Copyright © 2008 [cit. 11.02.2021]. Dostupné z: https://www.circularity-gap.world/2020

4 Linear economic model, illustration: Bára Růžičková

5 Procedures according to the model of Circular Economics, illustration: Bára Růžičková

6 Interview with Vladimír Kočí: We cannot see beyond the horizon with common sense. Material times. Prague: Happy Materials, 2019. ISSN 2464-742X.ii

7 So far, this is only a general plan, for which a strategy is gradually being developed - to support sustainable industry, the circular economy and related waste management. However, a bill banning certain types of disposable plastics (cutlery, plates, straws, cups) was not approved by the Czech government until January 2020. Ideally, it should apply from July 2021.